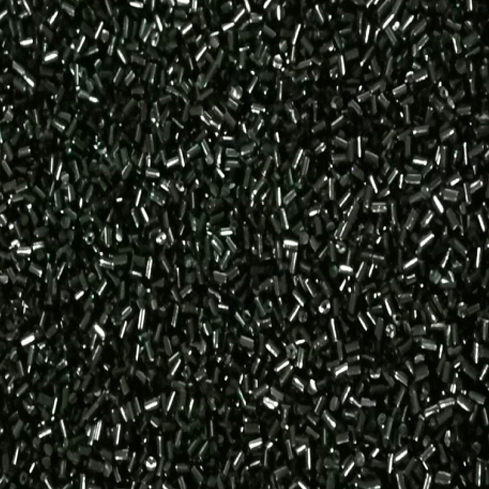

ナイロン 6 Chips Black – 優れた一貫性と均一な色分布

ナイロン 6

| Damaged length | National standardrequirements-Level B ≤100mm |

| Afterflame time | National standardrequirements-Level B ≤2s |

| Afterglow time | National standardrequirements-Level B ≤2s |

| Damaged length | Nylon 6-Flame Retardant febric-warp direction (after washing 50 回) =97mm |

Welcome our new Nylon 6 チップスブラック, our high-quality fabric production solution is here. Our unique approach involves using black chips right through to the last step of the polymerization which makes the color distribution very uniform and also improves on the performance. Especially suitable for those operations requiring gens and consistency, such an exceptional innovation is setting up new benchmarks in the textile segment.

Function:

ナイロン 6 Chips Black is meant to be used in production of textile materials, offering great colour stability and mechanical performance. This nylon has incorporated the black chips at the polymerization stage, and this guarantees that the colour goes through the material and does not form blotches, as is common with other nylons. This leads to a material that is consistently of a high quality and an enduring finish that is perfect for most uses.

特徴:

- Even Color Distribution: The new way of incorporating, the black chips, during the polymerization guarantees equal color throughout the nylon chips. This method also stands in contrast to previous techniques in which black color concentrate was physically blended with nylon chips; this method yielded irregular shades of coloring, as well as unstable coloring.

- Enhanced Consistency: Our approach comes out more stable and consistent since we do not mix the color concentrates. This stability in that particular fabric means that one would get consistent and satisfactory results of the final fabric.

- 優れた品質: Contrary to color concentration mix, the direct incorporation of black chips during polymerization does not present with any problem, this makes it possible to produce a quality nylon chip ideal for textile manufacturing.

- Improved Fabric Performance: this even texturing of the material presents a beautiful quality to the fabric, and it makes the products look fuller and very neat which is very important to textile products that are valued. This also has the overall effect of improvement in the quality of the fabric mainly concerning its width, density and strength due to the combination of the threads in this manner.

- Versatility: It is versatile product that Nylon 6 Chips Black can be used in fashion textile products as well as for industrial fabric. It can give very stable colors and is thus suitable for products for which both aesthetic looks and performance play a decisive role.

Performance Test

| National standard requirements-Level B | Nylon 6-Flame Retardant fabric-warp direction (after washing 50 回) | Nylon 6-Flame Retardant fabric-weft direction (after washing 50 回) | |

| Damaged length | ≤100mm | =97mm | =90mm |

| Afterflame time | ≤2s | =1.5s | =1.7s |

| Afterglow time | ≤2s | =0s | =0s |

| General nylon 6 | General nylon 66 | General polyester | Nylon 6-Flame Retardantfabric(Before washing) | Nylon 6-Flame Retardantfabric(After washing 50 times) | ||

| Warp direction | Weft direction | Warp direction | Weft direction | |||

| 20-22% | 20-22% | 20-22% | 35.2% | 33.1% | 34.4% | 32.7% |

ALWAYS DO YOUR BEST

能力をひとつにまとめる, partnering with our customers to innovate and inspire what's next.