BLOG

Is Spandex Factory Going Green? How Sustainability Is Changing the Industry

The spandex industry is often associated with high-performance fabrics used in sportswear, activewear, and fashion. But what if we told you that the production of these stretchy materials is undergoing a major transformation? Spandex Factory, like Highsun Holding Corporation, is pioneering new sustainable practices that are not only changing how spandex is made but also reducing its environmental impact. This blog will dive deep into how Spandex Factory is adopting sustainability, the innovations driving this change, and how manufacturers are rethinking production processes to align with a greener future.

The Green Revolution in Spandex Manufacturing

Spandex, also known as elastane, has been a favorite fiber in activewear and sports clothing due to its remarkable stretchability and comfort. However, spandex’s environmental footprint has been a growing concern. Traditionally, the process of manufacturing spandex involved significant water and energy consumption, along with the release of pollutants into the air and water. As demand for eco-friendly products rises, Spandex Factory, especially this like Highsun, is exploring ways to make their production processes more sustainable.

To meet these demands, companies are focusing on reducing harmful emissions, using more sustainable materials, and improving overall efficiency throughout the supply chain. Highsun, for instance, has embraced a closed-loop production system that minimizes waste and energy consumption. This involves reusing and recycling water used in manufacturing, reducing chemical runoff, and implementing more energy-efficient machinery. Additionally, the company’s commitment to transparency in production practices allows consumers and businesses alike to make more informed choices when sourcing spandex products.

Sustainable Spandex: Materials and Innovation

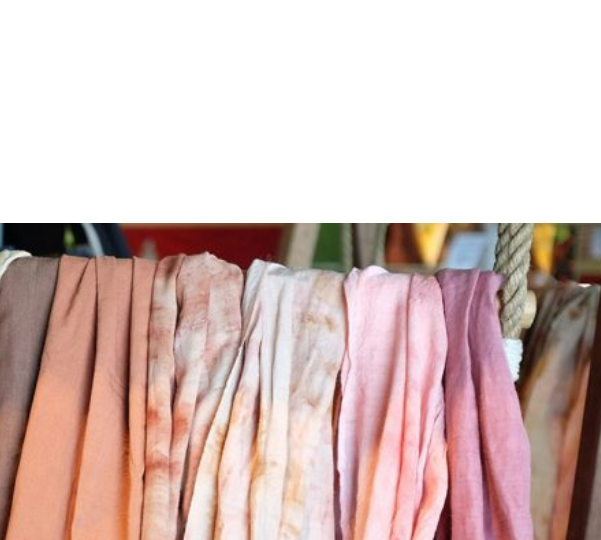

One of the key factors driving sustainability in the spandex industry is the development of more eco-friendly materials. Highsun’s Easy Dyeing Spandex, for example, represents a breakthrough in both performance and sustainability. The innovative yarn is engineered to withstand acidic dyeing conditions, achieving high color fastness and uniformity. This not only results in more vibrant and consistent colors but also reduces the need for harmful chemicals and excessive water usage typically involved in dyeing processes.

The Benefits of Easy Dyeing Spandex:

Enhanced Dyeing Performance: Traditional spandex often suffers from poor dye uptake, leading to uneven colors and requiring more chemicals to correct the issue. Easy Dyeing Spandex, however, is designed to absorb acid dyes efficiently, reducing both energy consumption and chemical waste.

Cost Efficiency: By reducing the need for additional dyes and chemicals, manufacturers can save costs and also lower their environmental impact. This makes it an attractive option for companies seeking to improve both their bottom line and their sustainability profile.

Another significant innovation in sustainable spandex production is the increased use of recycled materials. Many spandex manufacturers, including Highsun, are incorporating recycled polyester or nylon fibers into their products, which reduces the reliance on virgin raw materials and lowers carbon emissions associated with production.

The Role of Energy Efficiency in Spandex Factories

Energy consumption is one of the largest contributors to the environmental impact of textile manufacturing. In the case of spandex, the spinning, texturing, and dyeing processes can require substantial amounts of energy. As part of its green strategy, Highsun has focused on increasing energy efficiency across all stages of production. This includes investing in state-of-the-art machinery that reduces power consumption without compromising the quality of the final product.

Energy Saving Practices in Spandex Factory:

Advanced Technology: The adoption of energy-efficient machines, such as low-energy spinning frames and heat recovery systems, helps reduce the overall energy demand in the factory.

Optimized Production Processes: Highsun also utilizes smart factory systems to monitor energy usage in real time, allowing them to adjust production schedules and machinery settings to minimize unnecessary power consumption.

By making these changes, Spandex Factory not only saves costs but also significantly reduces its carbon footprint. For large-scale operations like Highsun, these steps can lead to a meaningful reduction in the company’s overall environmental impact.

Reducing Waste and Promoting Circular Economy

One of the most promising developments in the spandex industry is the push toward a circular economy. This involves designing products and processes that minimize waste and enable the recycling and reuse of materials. For spandex factories, this means creating systems that allow for the recycling of waste materials, such as off-cuts and defective yarns, into new products.

Highsun has implemented several initiatives to promote circularity in its production process. By recycling spandex waste into new fibers or repurposing it for other applications, the company is able to reduce its waste output and use fewer raw materials. This not only minimizes landfill waste but also reduces the need for the extraction of natural resources, further reducing the factory’s environmental impact.

Additionally, the use of recycled spandex fibers in products like activewear and swimwear has been a growing trend. These fibers are sourced from post-consumer waste, such as discarded garments, which helps keep textiles out of landfills and gives them a second life. As consumer demand for sustainable products increases, more companies are likely to adopt similar practices, making spandex a more eco-friendly option in the textile industry.

The Future of Spandex Factory: What’s Next in Sustainability?

As the global textile industry continues to evolve, sustainability will remain a key driving force. Spandex Factory, like Highsun, is constantly innovating to reduce its environmental footprint while maintaining the high-performance standards that the industry demands. The future of spandex production is likely to see even more advancements in eco-friendly materials, energy-efficient processes, and circular manufacturing.

Emerging Trends in Sustainable Spandex Production:

Bio-based Spandex: One of the most exciting possibilities is the development of bio-based spandex fibers made from renewable sources such as plant-based materials or bio-polymers. These fibers could provide a more sustainable alternative to the petrochemical-based spandex currently used in many applications.

Waterless Dyeing Technologies: Waterless dyeing technologies are another promising avenue for reducing the environmental impact of spandex manufacturing. By eliminating the need for water in the dyeing process, these technologies could dramatically reduce water consumption and chemical use in the textile industry.

Blockchain for Transparency: The use of blockchain technology to track the entire lifecycle of spandex products—from raw material sourcing to production and shipping—could become more common. This would allow consumers to see exactly how sustainable their spandex products are and encourage more responsible sourcing practices.

As consumers and businesses become more conscious of their environmental impact, the demand for sustainable spandex options will continue to rise. Factories that invest in green technologies, eco-friendly materials, and ethical production practices will be well-positioned to meet this demand while contributing to a more sustainable future for the textile industry.

Conclusion: Spandex Factory and the Path to Sustainability

The spandex industry is no longer just about stretch and performance; it’s also about reducing environmental impact and embracing sustainable practices. Highsun and other forward-thinking spandex manufacturers are leading the charge by adopting innovative technologies and materials that prioritize sustainability without sacrificing quality. From energy-efficient production processes to recycled fibers and eco-friendly dyeing techniques, the industry is moving toward a greener future.

For manufacturers and consumers alike, the shift toward sustainable spandex offers a unique opportunity to create high-performance textiles while also minimizing environmental impact. As sustainability becomes an increasingly important factor in the global textile market, spandex factories will continue to evolve, ensuring that the fabric of the future is not only functional but also environmentally responsible.

LET'S TALK TOGETHER

Lorem ipsum dolor sit amet, consectetur estor adipi isicing elit, sed do eiusmod tempor este uterre incididui unt ut